Our Strategic Blueprint

I took on the CEO role last year because I see QuantumScape as the global leader in solid state battery technologies with an ability to revolutionize energy storage and create tremendous shareholder value in the process.

Tim Holme

Chief Technology Officer at QuantumScape

At QuantumScape, we have appreciated the surge in interest in solid-state batteries since we revealed our performance data at our battery showcase. We would like to elaborate on a few aspects of the data we presented at the showcase.

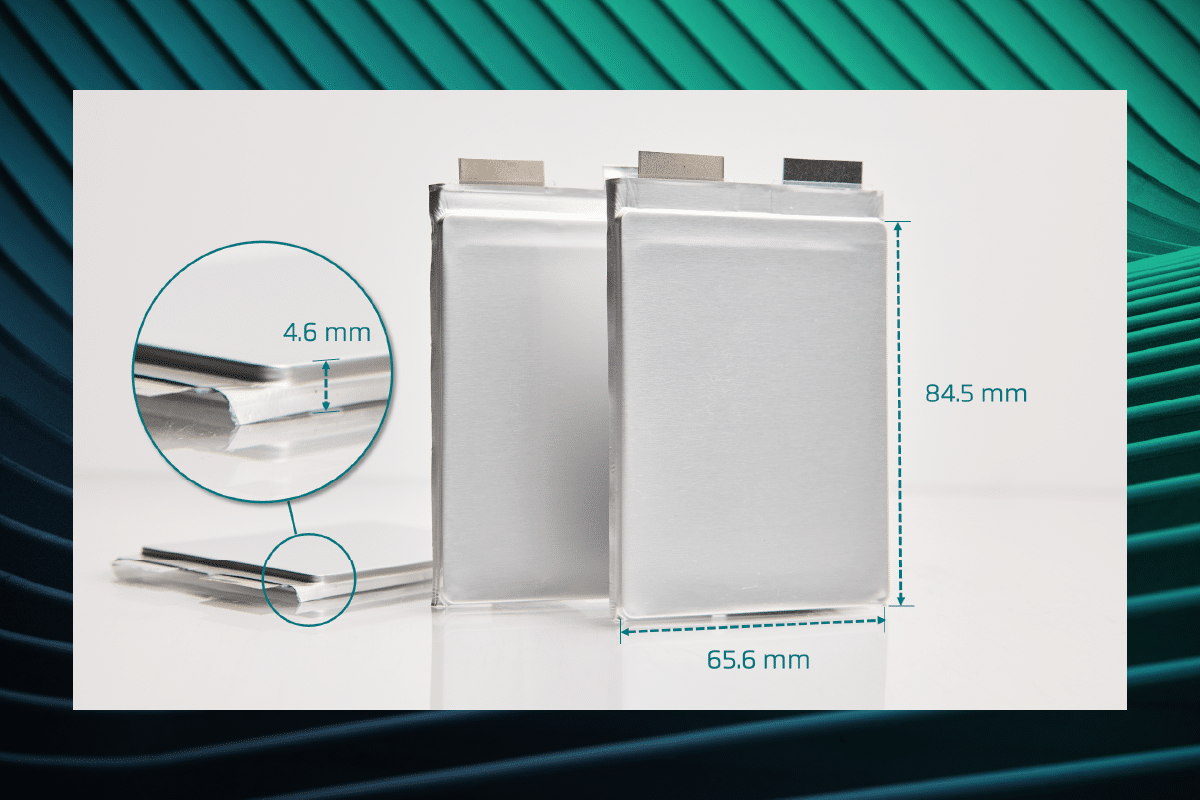

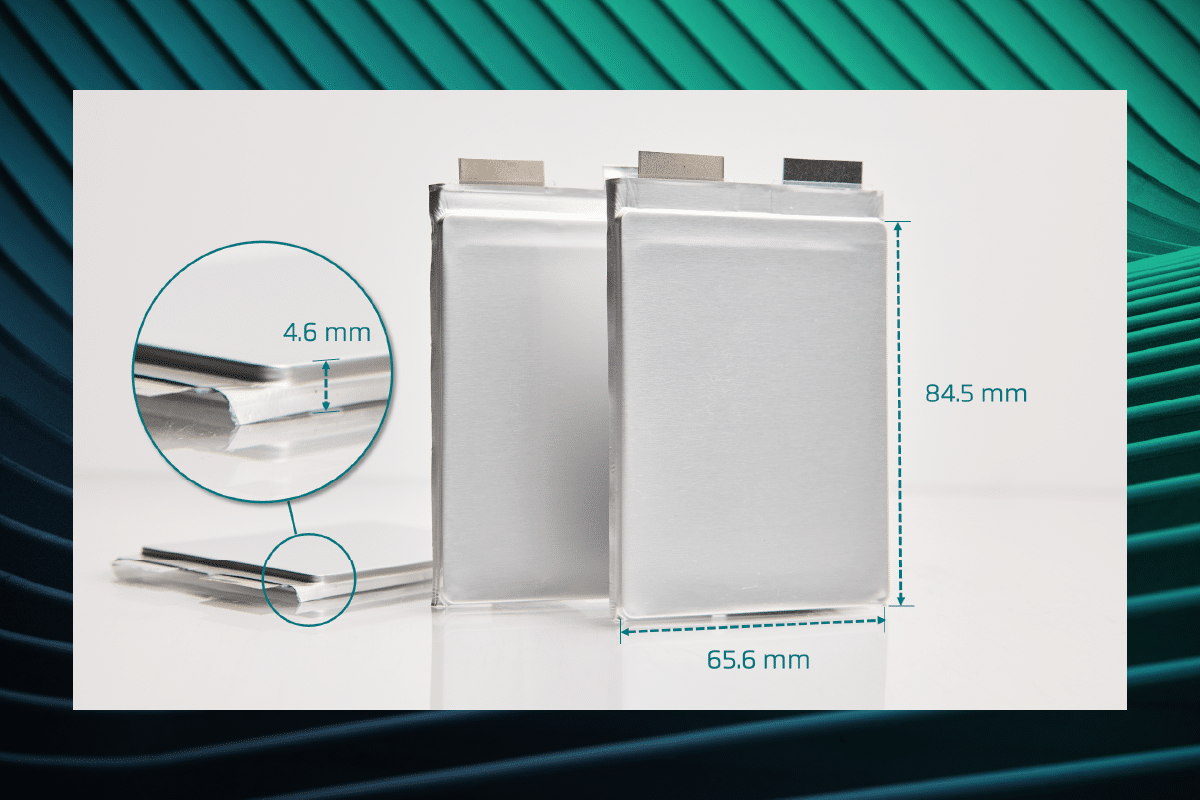

Let’s start by reminding readers that QuantumScape’s battery technology is still in the development stage. We are currently testing battery cells with commercial dimensions of 70 x 85mm but only as a single layer, i.e., one cathode, one solid-state separator, and one in-situ formed lithium-metal anode. As noted in our SEC filings, there is much work ahead of us. Among other tasks, we need to develop multi-layer cells and scale up our manufacturing capabilities. If we are successful in these efforts, we aim to start series production of our battery cells in 2024.

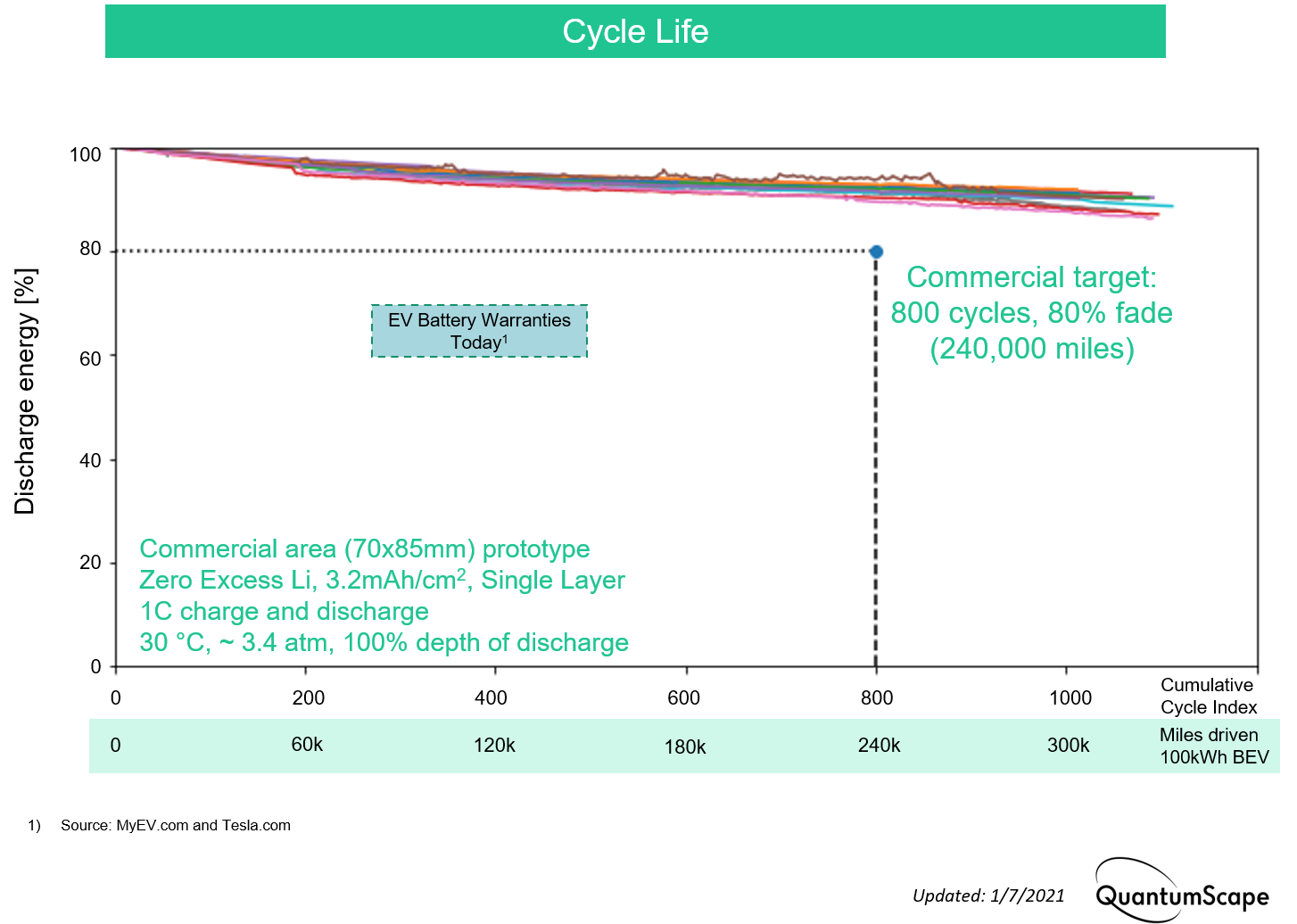

At our battery showcase, we presented data showing cycle life under a number of different test conditions: aggressive driving conditions at 1C/1C rates; race track driving conditions; and at low temperature (-10 °C).

For typical battery cycle life testing, many batteries are run at C/3 rates, which means the cells are charged in three hours and discharged in three hours. For our cycle life demonstration, we used more aggressive testing conditions of 1C: full charge and discharge of the cell in one hour each. Even under these more strenuous test conditions the QuantumScape single layer cells showed over 1,000 cycles to a median of over 90% energy retention. We report energy, not just capacity, because energy takes into account voltage fade and impedance growth. Note that this test was run at near-room temperature (30 °C), commercially-relevant current density (3.2 mA/cm2) and cathode loading (3.2 mAh/cm2), 100% depth of discharge, modest pressure (3.4 atm), commercial area, and zero lithium on the anode. We are not aware of any other solid-state efforts that have reported this level of performance under all these conditions simultaneously, which we believe is required for commercial viability.

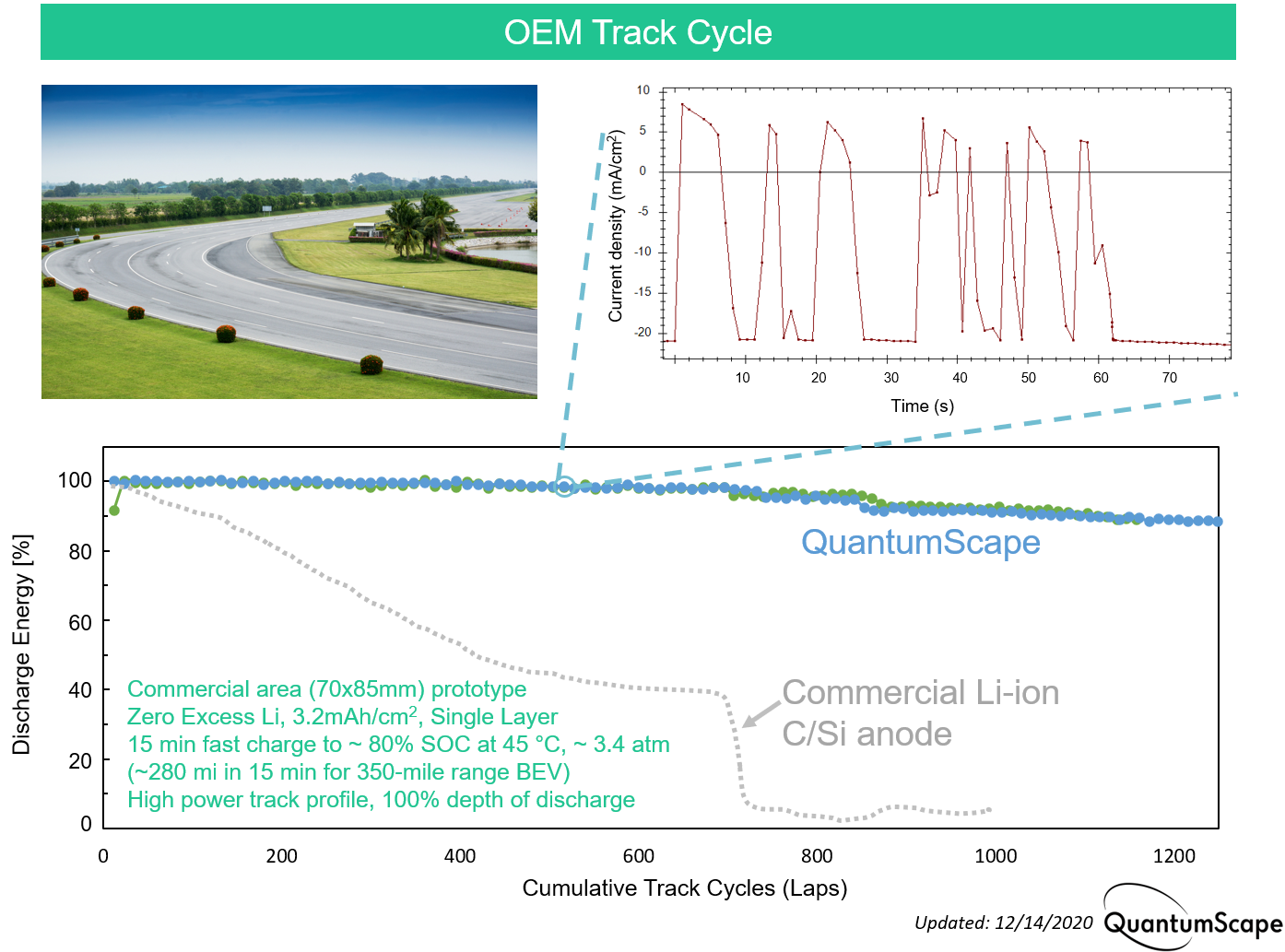

The race track drive cycle is among the harshest of battery cycling tests. Aggressive performance demands — involving repetitive extreme acceleration and braking followed by 15-minute fast-charging — will stress the system more and lead to more rapid degradation than normal driving conditions, which is why conventional lithium-ion BEV energy cells perform poorly on this test, as shown in the chart below. We were therefore very pleased to report that the QuantumScape cell performed significantly better on this test, delivering over 100 full charge-discharge cycles with 100% depth of discharge (i.e., 0-100% state of charge) with 90% retention of energy under these demanding conditions.

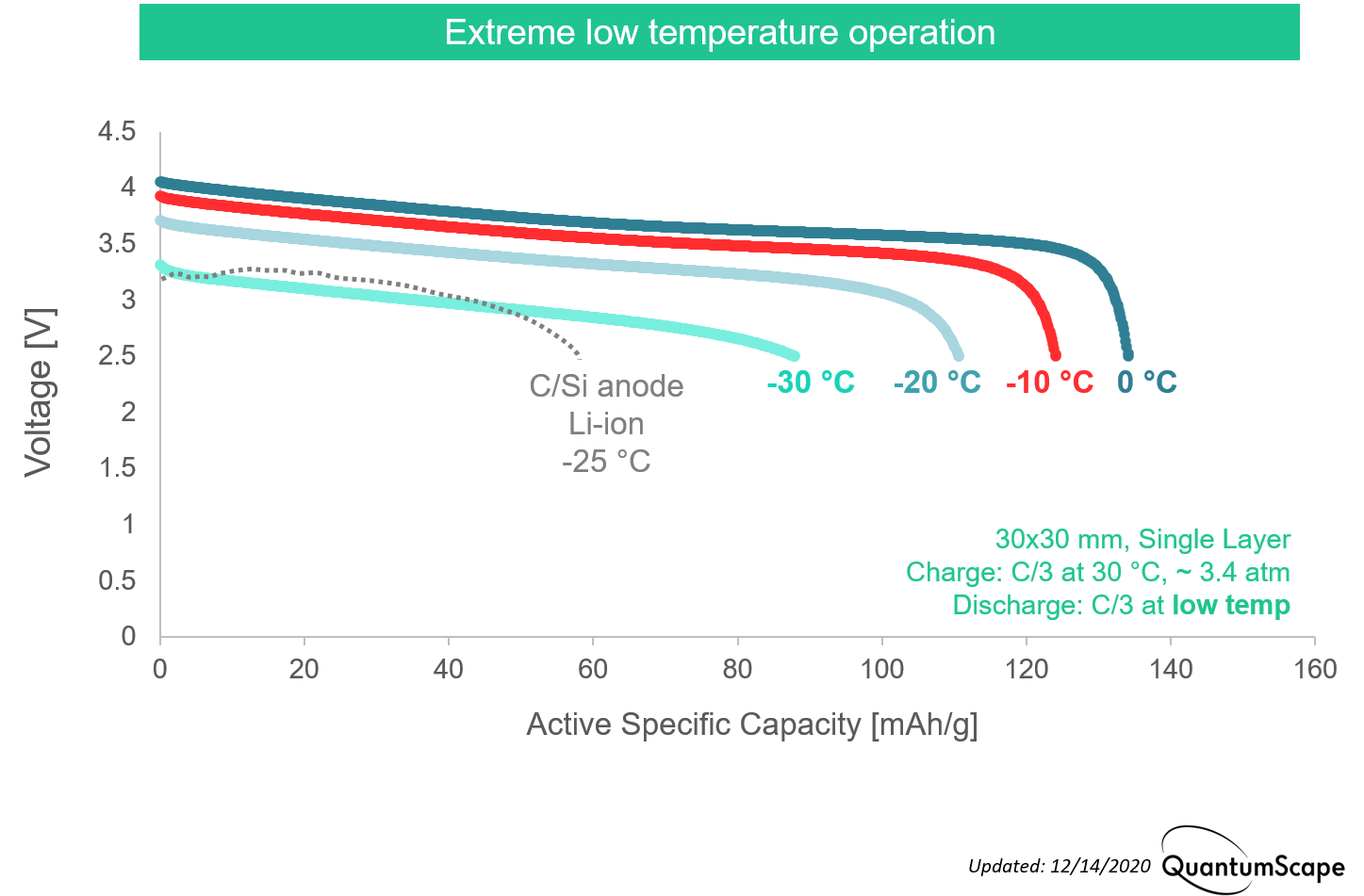

In addition to cycling data, we reported performance data for our soli-state material at extreme low temperatures, i.e., -30 degrees C. As the slide below shows, the data shows good energy retention even at these low temperatures — better than the reference state-of-the-art BEV lithium-ion cell shown on that slide. Batteries generally perform worse at low temperatures, but the requirement is to provide enough power to drive safely while the battery system heats itself.

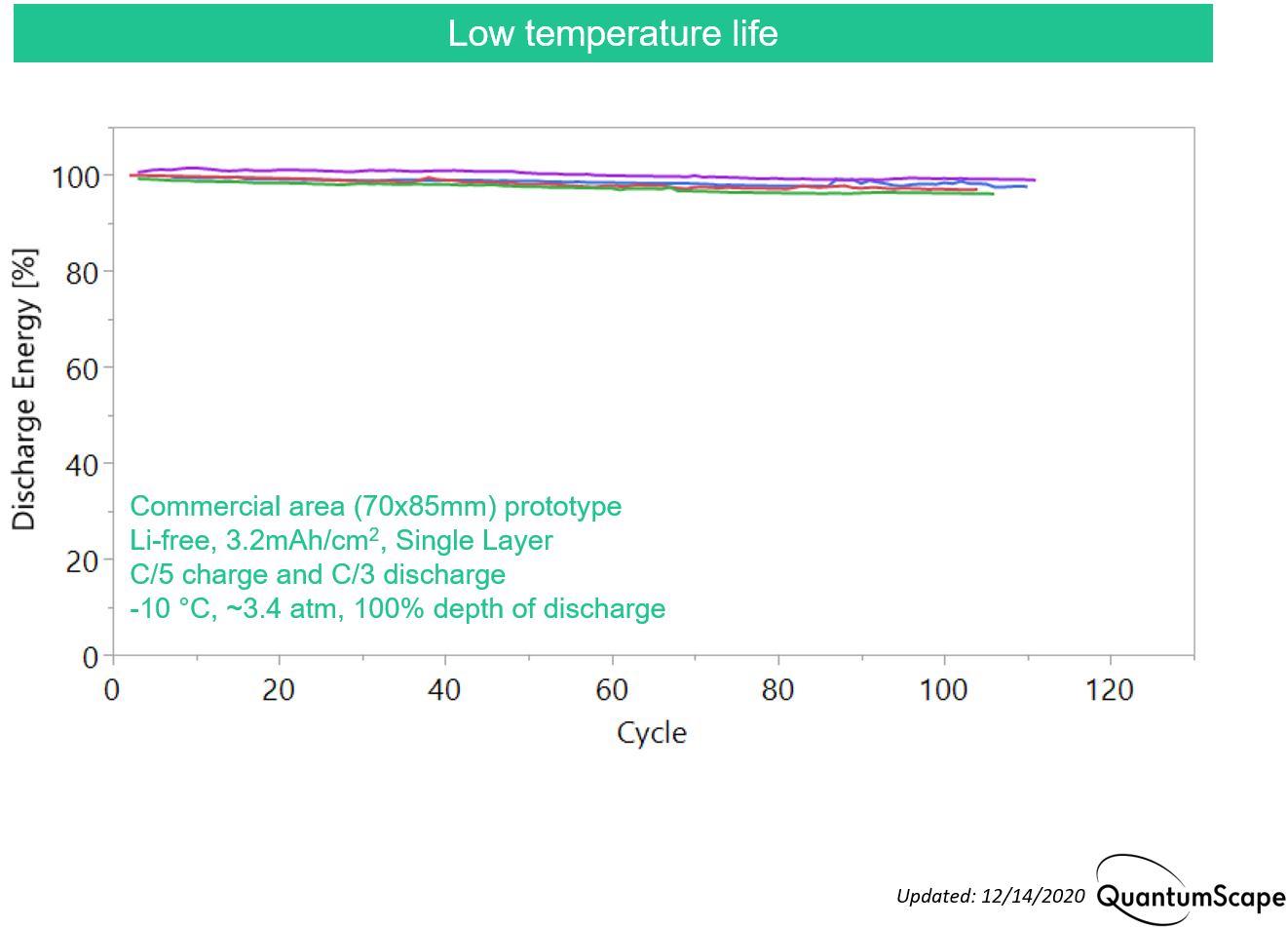

We also reported cycle life data for these single layer cells at -10 degrees C, important for real-world operation, shown on the graph below. We have not seen comparable cycling from any other solid-state effort.

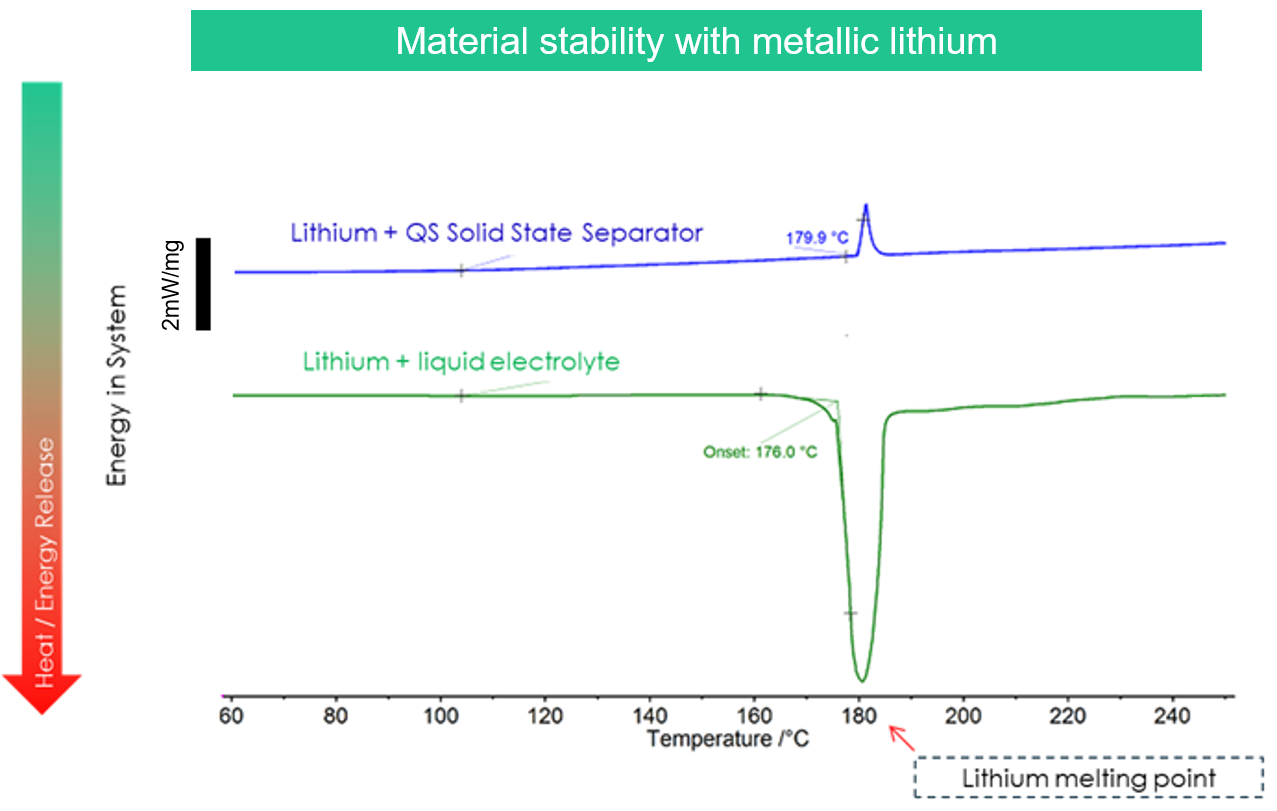

Finally, the differential scanning calorimetry (DSC) chart below shows what happens when lithium melts in contact with our separator – there is no exothermic reaction as is the case when lithium melts in contact with a liquid electrolyte. We believe that safety in our cell will be improved relative to lithium-ion because we have replaced the combustible polymer separator with a non-oxidizable (i.e., non-combustible) separator that is thermally stable to much higher temperatures than polymers, so it will act as a more effective barrier between anode and cathode.

We believe that the above results, in aggregate, redefine the performance frontier of solid-state batteries as no previous solid-state battery efforts have reported similar results under comparable conditions.

Multi-Layering – The next step for us is to utilize our single-layer cells as the building blocks for robust solid-state multi-layer cells. Making multi-layers requires significantly more material, tools and personnel — for example, a 10-layer cell requires fabricating ten times as many separators and cathodes, which requires either ten times as many tools and technicians or larger scale equipment, with multi-quarter lead times either way. In addition, making enough multi-layer cells to get statistically meaningful data requires producing many such cells, which requires automation engineering. This is part of why making a multilayer cell takes time even after one has working single-layer cells meeting performance specifications.

There have been some questions related to whether cathode expansion poses a challenge for multi-layer cell construction. Typical cathode material expansion is relatively small (1-5%) and occurs in both lithium-ion and solid-state batteries, so we do not expect this expansion to introduce any meaningful difficulty making multilayer solid-state batteries relative to conventional batteries. If cathode expansion were indeed a failure mode, it would show up in the single-layer cell cycling data as well as multilayer cells. Given the >1,100 cycle life data we’ve shown on single layer cells, this is clearly not the case.

Pressure – Our testing was conducted at a moderate pressure of 3.4 atm which is substantially lower than the pressure required for some other lithium metal systems, which can require 10-20 atm. We will continue to work to reduce this moderate level of pressure to lower levels as we develop our battery technology.

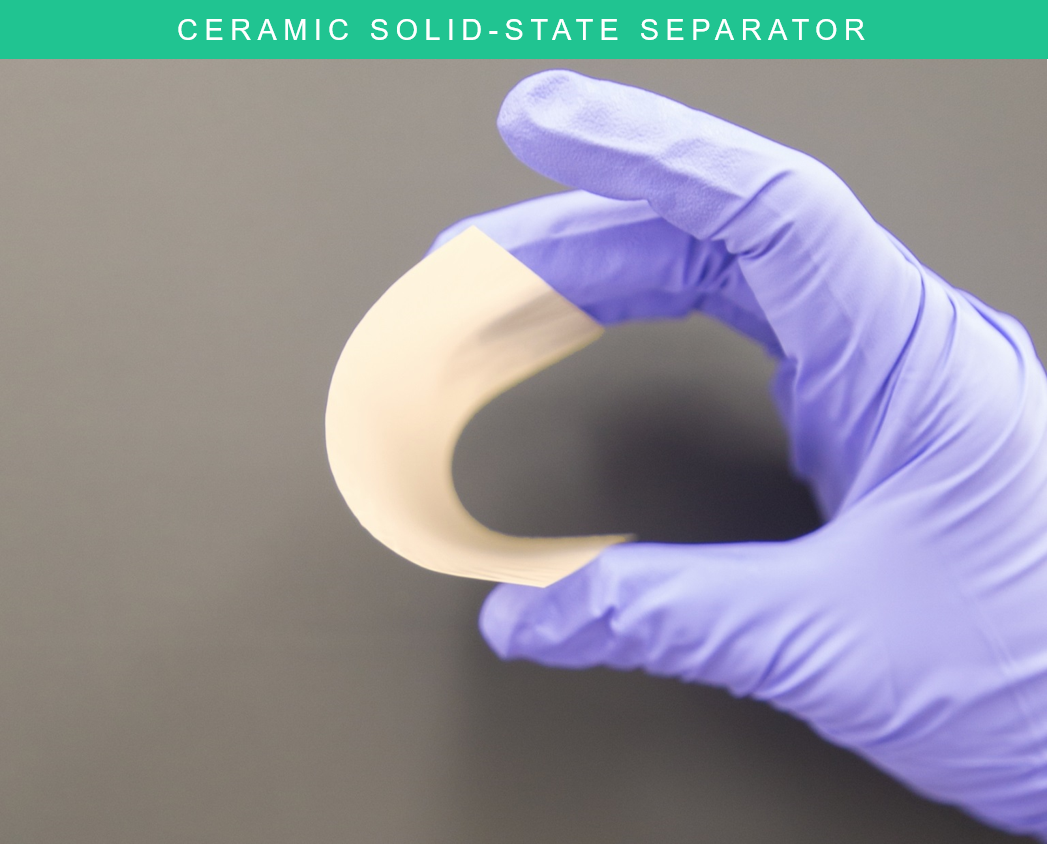

Dendrites and Stiffness – Our solid-state separator is flexible and is demonstrably not stiff.

Solving the problem of dendrites is very difficult as lithium can dendrite through polymers, single crystals, and glassy materials with no grain boundaries, as well as polycrystalline materials with grain boundaries, so none of those microstructures is by itself a solution to the dendrite problem. That is why we have been so excited at QuantumScape to have developed a material and system that we believe can address this issue.

Energy Density and Cost – Our target is to stack several dozen of our single layer unit cells together into a multilayer cell and achieve a target energy density of 1,000 Wh/L, enabled by the elimination of the anode host material. This would allow greater range than today’s state-of-the-art commercially shipping BEV cells, such as the 2170 cell used in the Tesla Model 3 which has an energy density of 713 Wh/L, as reported by CleanTechnica. The higher energy density design targeted by the QuantumScape cells also reduces cost by eliminating both the anode material and the anode manufacturing line, while simplifying the formation and aging process, one of the most expensive parts of the battery manufacturing process. Our separator consists of generally inexpensive precursor materials and utilizes processes suitable for high volume continuous flow production.

In summary, when evaluating battery performance test data, it is important to note that there are many compromises in test conditions that can be made when showing battery cycle life data, many of which result in a cell that is not capable of meeting commercial requirements. What makes QuantumScape’s performance data interesting is not just that it shows over 1,000 cycles with good capacity retention, but that it does so under commercially-relevant conditions, including high current density, close-to-room temperature, full depth of discharge, modest pressure, zero excess lithium, and commercially-relevant area and cathode loading. We hope this explanation helps provide a better understanding of the data we have shared and our progress towards developing solid-state lithium-metal batteries.

Please note that the information in this posting includes “forward-looking statements” within the meaning of Section 27A of the Securities Act and Section 21E of the Securities Exchange Act of 1934, as amended. All statements, other than statements of present or historical fact, are forward-looking statements. These forward-looking statements are based on management’s current expectations and assumptions about future events and are based on currently available information as to the outcome and timing of future events.

These forward-looking statements involve significant risks and uncertainties that could cause the actual results to differ materially from the expected results. Most of these factors are outside QS’s control and are difficult to predict. Factors that may cause such differences include, but are not limited to: (i) QS faces significant barriers in its attempts to scale from a single layer pouch cell and complete development of its solid-state battery cell and related manufacturing processes, and development may not be successful, (ii) QS may encounter substantial delays in the development, manufacture, regulatory approval, and launch of QS solid-state battery cells, which could prevent QS from commercializing products on a timely basis, if at all, (iii) QS may be unable to adequately control the costs of manufacturing its solid-state separator and battery cells, and (iv) QS may not be successful in competing in the battery market. QS cautions that the foregoing list of factors is not exclusive. Additional information about factors that could materially affect QS is set forth under the “Risk Factors” section in the prospectus filed with the SEC on December 31, 2020 and available on the SEC’s website at www.sec.gov.

Forward-Looking Statements

This article contains forward-looking statements within the meaning of the federal securities laws and information based on management’s current expectations as of the date of this current report. All statements other than statements of historical fact contained in this article, including statements regarding the future development of QuantumScape’s battery technology, the anticipated benefits of QuantumScape’s technologies and the performance of its batteries, and plans and objectives for future operations, are forward-looking statements. When used in this current report, the words “may,” “will,” “estimate,” “pro forma,” “expect,” “plan,” “believe,” “potential,” “predict,” “target,” “should,” “would,” “could,” “continue,” “believe,” “project,” “intend,” “anticipates” the negative of such terms and other similar expressions are intended to identify forward-looking statements, although not all forward-looking statements contain such identifying words.

These forward-looking statements are based on management’s current expectations, assumptions, hopes, beliefs, intentions, and strategies regarding future events and are based on currently available information as to the outcome and timing of future events. These forward-looking statements involve significant risks and uncertainties that could cause the actual results to differ materially from the expected results. Many of these factors are outside QuantumScape’s control and are difficult to predict. QuantumScape cautions readers not to place undue reliance upon any forward-looking statements, which speak only as of the date made. Except as otherwise required by applicable law, QuantumScape disclaims any duty to update any forward-looking statements. Should underlying assumptions prove incorrect, actual results and projections could differ materially from those expressed in any forward-looking statements. Additional information concerning these and other factors that could materially affect QuantumScape’s actual results can be found in QuantumScape’s periodic filings with the SEC. QuantumScape’s SEC filings are available publicly on the SEC’s website at www.sec.gov.

I took on the CEO role last year because I see QuantumScape as the global leader in solid state battery technologies with an ability to revolutionize energy storage and create tremendous shareholder value in the process.

QuantumScape’s planned first commercial product, QSE-5, is a ~5 amp-hour cell designed to meet the requirements of automotive applications. Here, we’ll walk through the various elements of the cell specifications and explain some of the complexities behind the seemingly simple metric of energy density.

I took on the CEO role last year because I see QuantumScape as the global leader in solid state battery technologies with an ability to revolutionize energy storage and create tremendous shareholder value in the process.

QuantumScape’s planned first commercial product, QSE-5, is a ~5 amp-hour cell designed to meet the requirements of automotive applications. Here, we’ll walk through the various elements of the cell specifications and explain some of the complexities behind the seemingly simple metric of energy density.

Privacy Policy | Terms of Use

© 2025 QuantumScape Battery, Inc.

1730 Technology Drive, San Jose, CA 95110

info@quantumscape.com

Pamela Fong is QuantumScape’s Chief of Human Resources Operations, leading people strategy and operations, including talent acquisition, organizational development and employee engagement. Prior to joining the company, Ms. Fong served as the Vice President of Global Human Resources at PDF Solutions (NASDAQ: PDFS), a semiconductor SAAS company. Before that, she served in several HR leadership roles at Foxconn Interconnect Technology, Inc., a multinational electronics manufacturer, and NUMMI, an automotive manufacturing joint venture between Toyota and General Motors. Ms. Fong holds a B.S. in Business Administration from U.C. Berkeley and a M.S. in Management from Stanford Graduate School of Business.