Our Strategic Blueprint

I took on the CEO role last year because I see QuantumScape as the global leader in solid state battery technologies with an ability to revolutionize energy storage and create tremendous shareholder value in the process.

Despite significant advancements in lithium-ion batteries over the last two decades, there are limits to their energy density and fast charge capabilities. This means they may not be suitable for applications that require very high energy density, such as long-range EVs, electrical aircraft, or advanced consumer electronics devices.

In this second blog article in our series on energy density, we’ll focus on how to maximize energy density with better active materials and denser electrodes (cathode and anode).

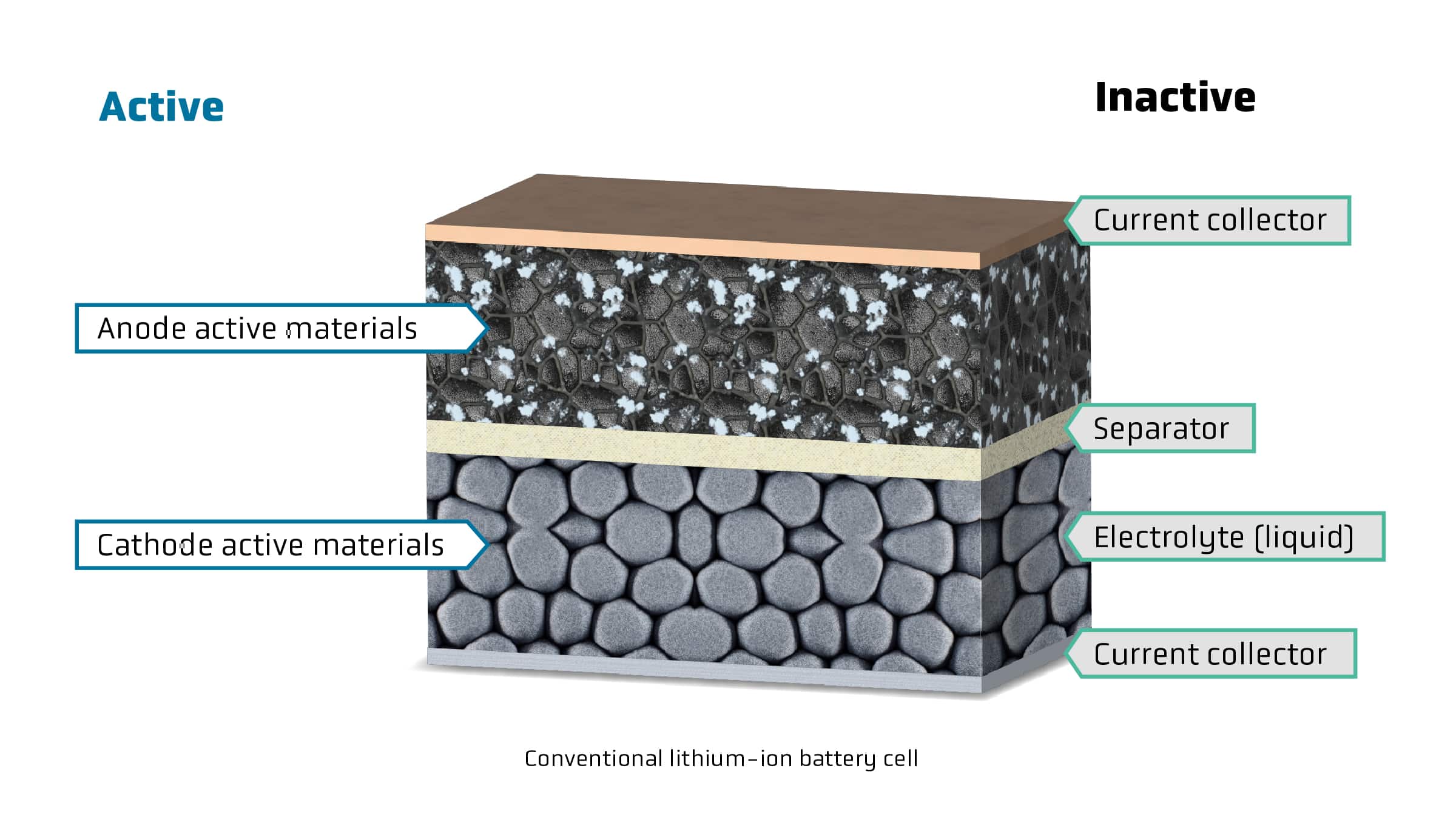

Active vs inactive materials

Lithium-ion batteries are essentially composed of two categories of materials – active and inactive. For most batteries, there are active and inactive materials on both the anode and cathode sides of the cell.

There are two main ways to maximize energy density – 1) use active materials that can store more energy; 2) increase the percentage of active material in the cell compared to its inactive materials.

Anode Active Materials

The most common active material in conventional anodes is graphite. Graphite has been used for decades in lithium-ion batteries and its properties are very well understood. However, graphite pales in comparison to the theoretical capacity of alternatives such as silicon or lithium metal.

The highest energy-density batteries today use a small amount of silicon mixed with graphite to boost the capacity of the anode a bit. But lithium metal – QuantumScape’s approach – has the highest specific capacity1 of any anode in a lithium-based system; we explain this in detail in The Advantages of Lithium-Metal Anodes.

Cathode Active Materials

To maximize the amount of energy storage [mAh/g] in the cathode, it must match the capacity [mAh] that is stored in the anode. Nickel-rich cathodes, such as nickel-rich nickel manganese cobalt (NMC) or nickel cobalt aluminum (NCA), are high-performance cathodes. They have both relatively high capacity and high voltage,2 which means they have more energy storage capability per gram of material. Lithium iron phosphate (LFP) is another popular cathode chemistry; it has lower energy than high-performance cathodes like NMC and NCA and is typically used when optimizing for cost.

Cathode and anode loading: A balancing act

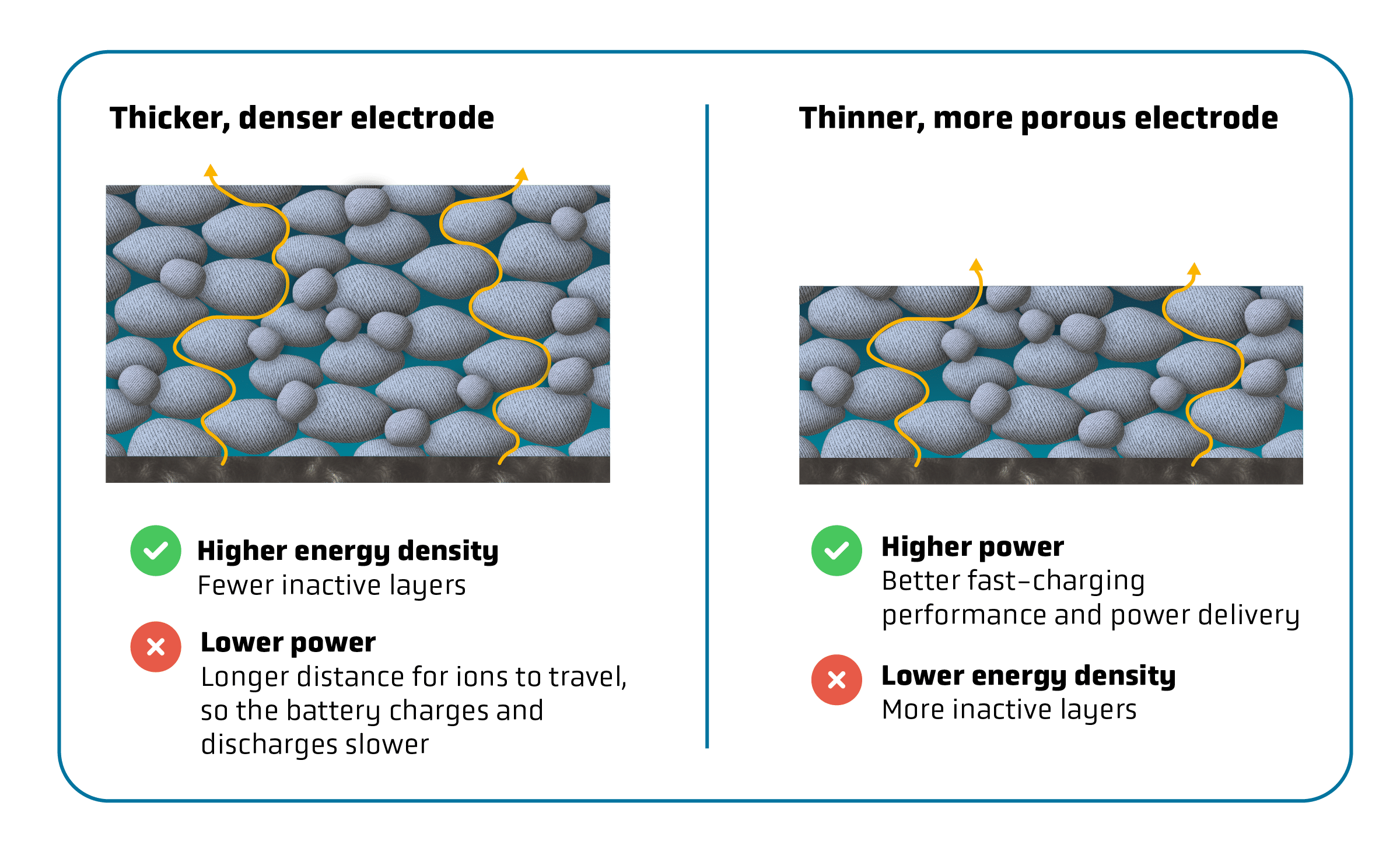

In conventional batteries, cell energy density can be boosted by adding more cathode and anode active material to each layer (higher electrode loading) and making the electrodes denser (lower porosity). More energy can thus be stored in each layer with fewer layers per cell. Since each layer also has deadweight inactive material, thicker electrodes can boost cell energy density to a certain degree.

Why not make a one-layer cell with ultra-thick, very dense cathode and anode to minimize the proportion of inactive materials?

While creating a super thick and dense single-layer battery cell might increase the energy density, extracting that energy becomes more difficult. As the electrode thickness and/or density increases, the lithium ions leaving the cathode or entering the anode are bottlenecked, due to increases in the distance the lithium ions must travel and the tortuosity, or twistedness, of the path from one electrode to another.3

This higher tortuosity and longer travel path limit the battery’s power – how quickly energy can be delivered or received by the battery.

This basically explains the trade-off between energy and power4: optimizing a battery for one often results in a decrease in the other, making it challenging to serve applications, such as electric vehicles, that require both. (For more information, see our blog on fast-charging performance.)

Given the need to balance the cathode and anode and maintain acceptable power performance, conventional lithium-ion batteries begin to experience diminishing returns from thicker and more dense electrodes, typically around ~5 mAh/cm2.5

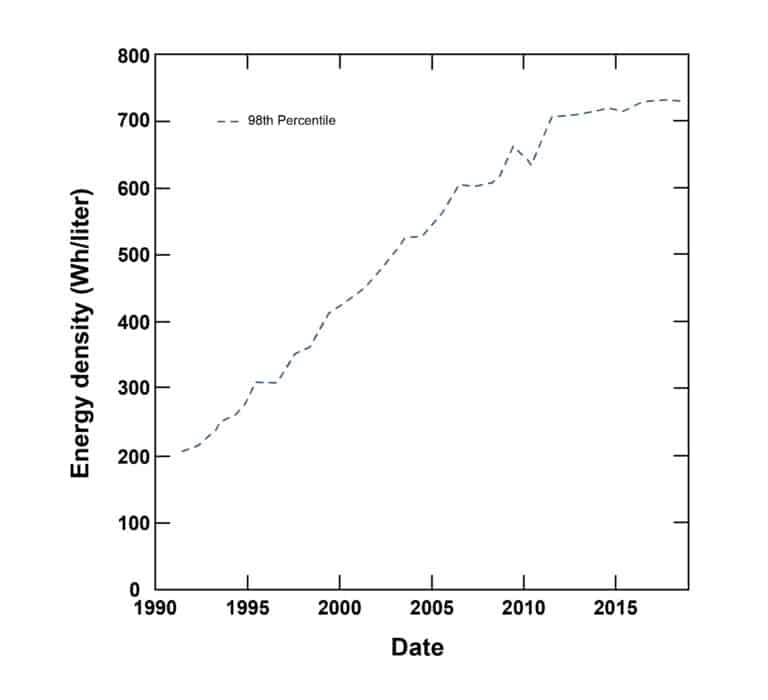

This chart shows the increases in energy density of the top-performing commercial lithium-ion batteries over time; the trend line represents the 98th percentile (top 2%) of battery performance in volumetric energy density. Note the rate of improvement has slowed in recent years. Source: Energy Environ. Sci., 2021,14, 1635-1651

In concrete terms, today’s state-of-the-art lithium-ion battery cells can achieve approximately 750 Wh/L and 275 Wh/kg. However, the fundamental limits of both volumetric and gravimetric energy density are beginning to be reached. We need next-generation technologies to achieve higher energy density. For example, a more energy-dense anode material could allow the anode layer to be thinner or lighter (or both) while storing the same amount of energy from the cathode.

1Specific capacity [mAh/g] refers to the amount of electric charge [mAh] a material can deliver per gram of that material.

2 For more on these concepts, see our blog on capacity versus energy.

3 A thick cathode is like a dense, overgrown forest; the lithium cannot easily move through it in a straight line. A lithium atom moving along a very long and twisted path loses a greater percentage of its energy as heat, which reduces the battery’s efficiency. Not only that, at very high charge rates this heat can reach unsafe levels if not properly controlled.

4 Power is a measure of how quickly energy can be delivered or received by the battery and determines how fast a battery can charge or discharge. It is usually measured in watts (W).

5 “For the graphite NMC811 cell using LE, the improvement in both Eg and Ev is noteworthy when the areal loading increases up to ~5 mAh/cm2. For areal loadings above 5 mAh/ cm2, the contribution is less significant (Fig. 4B).” Source: https://doi.org/10.1038/s41467-021-25334-8

Forward-Looking Statements

This article contains forward-looking statements within the meaning of the federal securities laws and information based on management’s current expectations as of the date of this current report. All statements other than statements of historical fact contained in this article, including statements regarding the future development of QuantumScape’s battery technology, the anticipated benefits of QuantumScape’s technologies and the performance of its batteries, and plans and objectives for future operations, are forward-looking statements. When used in this current report, the words “may,” “will,” “estimate,” “pro forma,” “expect,” “plan,” “believe,” “potential,” “predict,” “target,” “should,” “would,” “could,” “continue,” “believe,” “project,” “intend,” “anticipates” the negative of such terms and other similar expressions are intended to identify forward-looking statements, although not all forward-looking statements contain such identifying words.

These forward-looking statements are based on management’s current expectations, assumptions, hopes, beliefs, intentions, and strategies regarding future events and are based on currently available information as to the outcome and timing of future events. These forward-looking statements involve significant risks and uncertainties that could cause the actual results to differ materially from the expected results. Many of these factors are outside QuantumScape’s control and are difficult to predict. QuantumScape cautions readers not to place undue reliance upon any forward-looking statements, which speak only as of the date made. Except as otherwise required by applicable law, QuantumScape disclaims any duty to update any forward-looking statements. Should underlying assumptions prove incorrect, actual results and projections could differ materially from those expressed in any forward-looking statements. Additional information concerning these and other factors that could materially affect QuantumScape’s actual results can be found in QuantumScape’s periodic filings with the SEC. QuantumScape’s SEC filings are available publicly on the SEC’s website at www.sec.gov.

I took on the CEO role last year because I see QuantumScape as the global leader in solid state battery technologies with an ability to revolutionize energy storage and create tremendous shareholder value in the process.

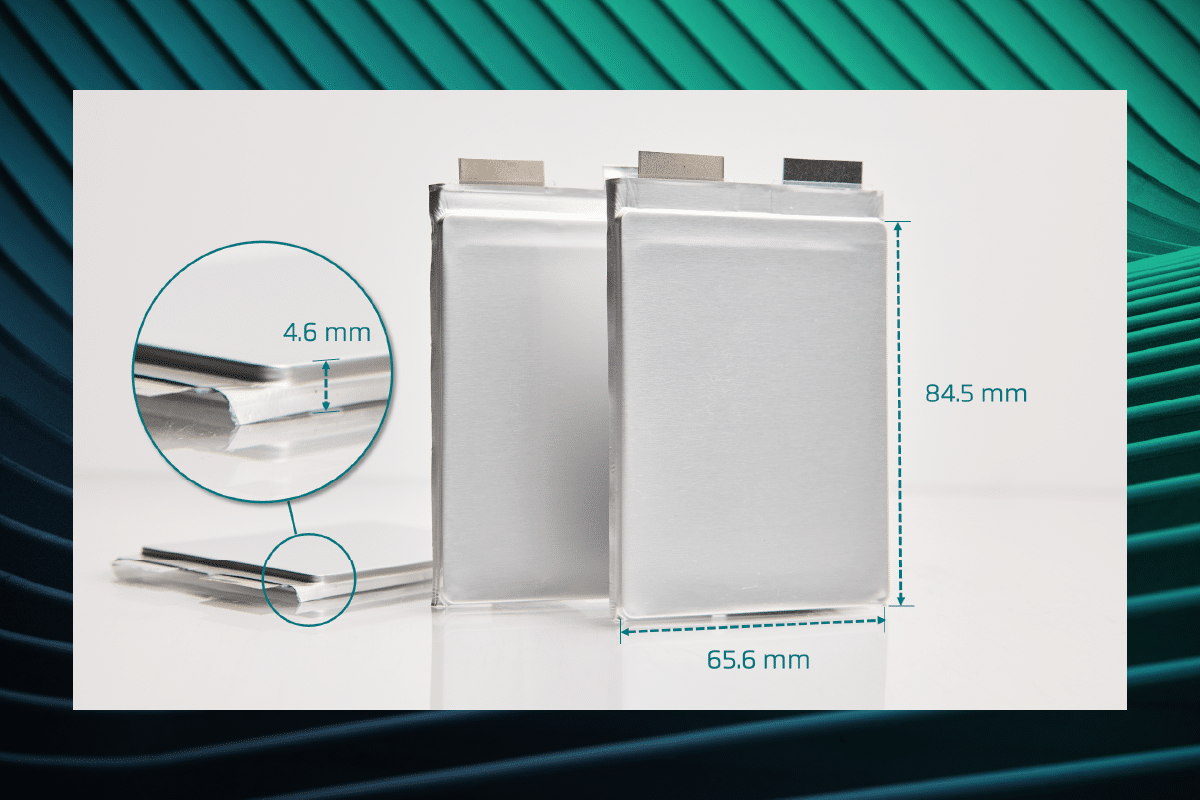

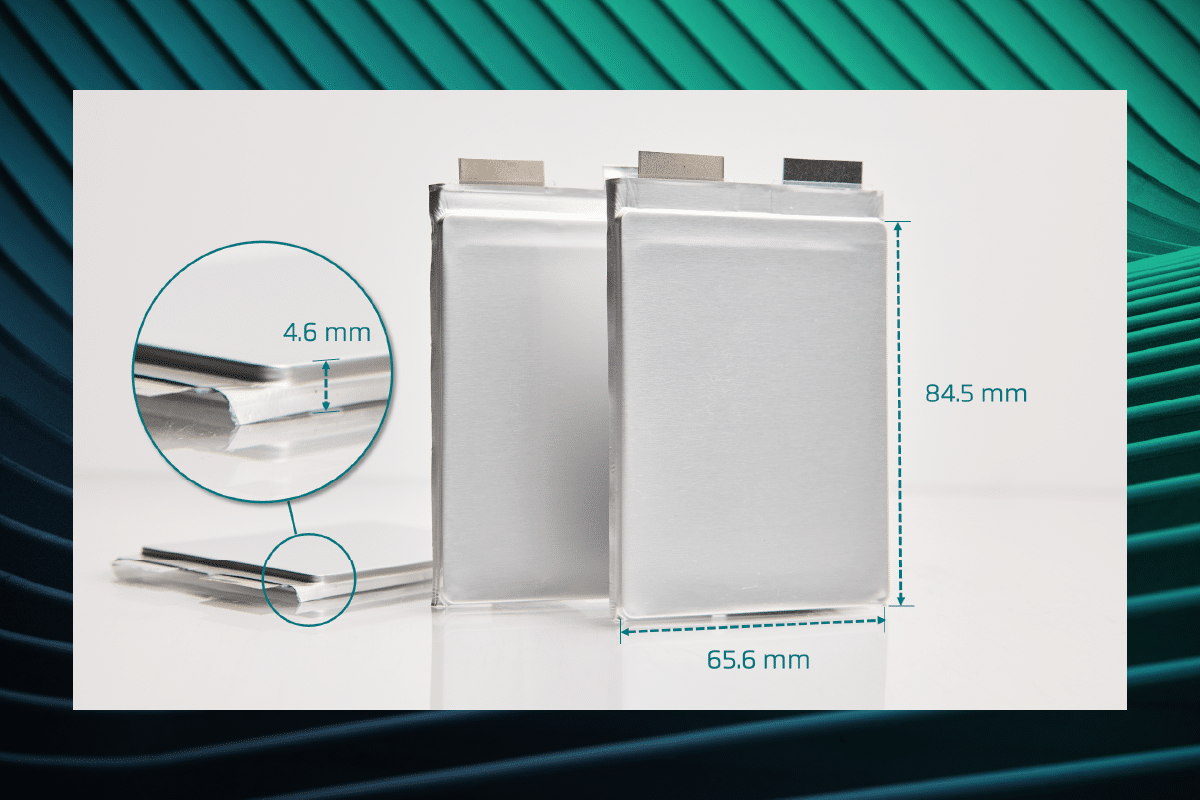

QuantumScape’s planned first commercial product, QSE-5, is a ~5 amp-hour cell designed to meet the requirements of automotive applications. Here, we’ll walk through the various elements of the cell specifications and explain some of the complexities behind the seemingly simple metric of energy density.

I took on the CEO role last year because I see QuantumScape as the global leader in solid state battery technologies with an ability to revolutionize energy storage and create tremendous shareholder value in the process.

QuantumScape’s planned first commercial product, QSE-5, is a ~5 amp-hour cell designed to meet the requirements of automotive applications. Here, we’ll walk through the various elements of the cell specifications and explain some of the complexities behind the seemingly simple metric of energy density.

Privacy Policy | Terms of Use

© 2025 QuantumScape Battery, Inc.

1730 Technology Drive, San Jose, CA 95110

info@quantumscape.com

Pamela Fong is QuantumScape’s Chief of Human Resources Operations, leading people strategy and operations, including talent acquisition, organizational development and employee engagement. Prior to joining the company, Ms. Fong served as the Vice President of Global Human Resources at PDF Solutions (NASDAQ: PDFS), a semiconductor SAAS company. Before that, she served in several HR leadership roles at Foxconn Interconnect Technology, Inc., a multinational electronics manufacturer, and NUMMI, an automotive manufacturing joint venture between Toyota and General Motors. Ms. Fong holds a B.S. in Business Administration from U.C. Berkeley and a M.S. in Management from Stanford Graduate School of Business.